Manufacturing

TradeRiver has identified the Manufacturing industry among a number of high growth industries where innovation and disruption are either happening or in desperate need of occurrence. Here’s a quick dive into all of the things we’ve highlighted about the Manufacturing industry.

Industry Insights

The US manufacturing industry is facing a challenging global industry landscape in areas such as talent retention, tariff uncertainty, trade constraints, etc. In an effort to find stability in an unpredictable market, organizations are getting their houses in order by making operations resilient and their business strategy agile.

Many companies are activating their digital muscle to improve performance and ensure brand longevity. In an effort to scale, manufacturers are forging new business partnerships, adding new capabilities to their bottom line, and reinforcing the core of their portfolios.

TradeRiver Highlights

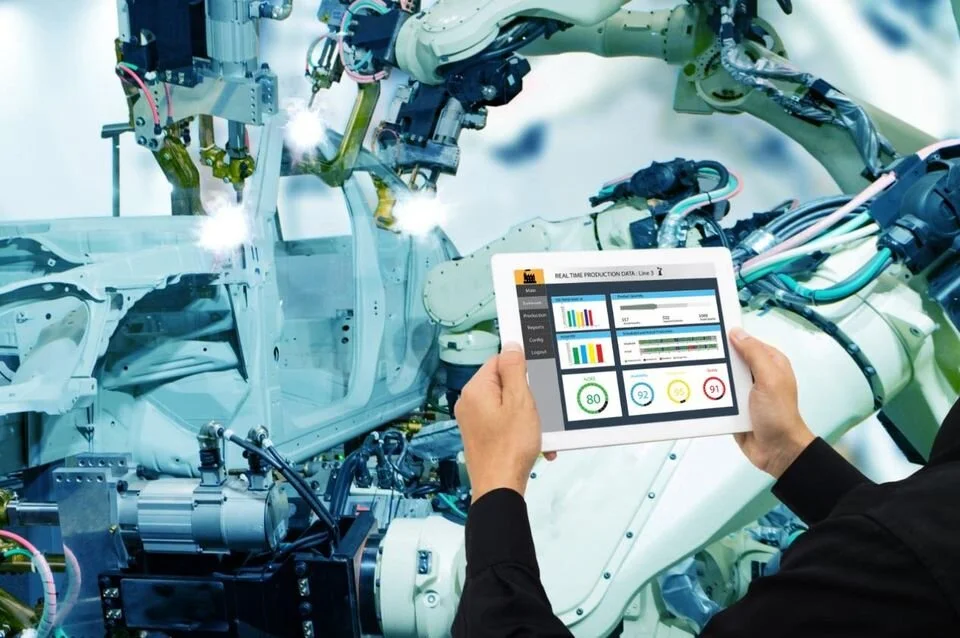

Robotics and automation tools are now foundational parts of warehouses and manufacturing facilities around the world. Unlike much other robotics and AI use cases, the technology has moved well beyond the theoretical into practice and is used by small suppliers and large companies like Amazon and Walmart. There’s still plenty of market left to transform every step of the supply chain and lots of room for players looking to adapt by redefining different verticals. Naturally, VCs are plenty eager to invest millions in technology.

Providing enhanced customer experiences has not typically been the primary focus of most manufacturers. Instead, most of the consumer-oriented efforts were left to retail and channel partners. But in today’s hyper-competitive market, customer-centricity has become just as important in the business-to-business (B2B) environment. With recent technology advancements, manufacturers now have an opportunity to not only capture more customer data but to analyze it in a way to better position their business for success. Companies are participating in this process otherwise known as the shift from B2B to B2B2C.

According to Deloitte's 2020 Manufacturing Outlook report, manufacturers are turning to partnerships for digital momentum. As manufacturers think about building agility into their supply chains, there is an increasing realization that these efforts cannot occur in isolation. The need to cultivate a strong ecosystem is a trend that has emerged. Research shows that it is an increasingly effective strategy for manufacturers, especially as it relates to digital momentum. Manufacturers are investing in this trend and believe the payout in the coming year is twofold.

While this digital transformation of the $10-trillion-plus global manufacturing sector will play out over a decade or more, pioneers are moving to drive bottom-line and top-line impact in the near term. The aerospace-and-defense industry is using digital tools to integrate an enormously complex supply network. A modern jet turbine engine has hundreds of individual parts, for example, some of which the engine manufacturer makes in-house and others it sources from a network of dozens of vendors. The complexity of sourcing can multiply quickly. Cloud computing-based tools allow suppliers to collaborate faster and more efficiently. Companies are utilizing information sharing and transparency in the supply chain to reduce required labor, reduce risk, and increase the speed of operations.

Apple became one of the first companies to reveal how the coronavirus was affecting its business, saying it was cutting its sales expectations for Q1. The novel coronavirus outbreak in China is affecting nearly every sector of tech manufacturing, leading analysts to reduce production estimates for everything from TVs and smartphones to laptops and video game consoles. As a result, companies are exploring ways to secure the supply chain and mitigate risks in order to protect operations and consumers. The outbreak is forcing companies to factor the cost of failure into their calculation and preemptively develop mitigation plans.

Transitioning to renewable energy sources, manufacturers are demonstrating success in doing well by doing good by generating new revenue streams through socially or environmentally conscious products and/or services. These initiatives, more often than not, contribute to profitability. The commitment toward green and clean energy continues in 2020 as numerous manufacturers are experimenting with multiple renewable energy resources for current and future energy procurement, including solar, wind, hydro, and geothermal.

New technologies are helping the manufacturing industry transition and adapt to the have-it-your-way economy. Personalized manufacturing strategies are bringing customization to a massive new scale. The market is begging for a return of craftsmanship.

Slowly, but surely, a design-it-yourself business model has grown in the manufacturing industry. Companies are increasingly practicing lean customization by running heavily on high tech and less on operation. With the combination of lean customization, just-in-time inventory, and digital technologies, companies can do customized manufacturing simply and efficiently.

While it is true that consumers are accustomed to acceleration and convenience, suppliers are starting to feel the pressure to satisfy insatiable consumers by delivering a variety of goods in smaller sizes at a faster pace.

Supply chains are adapting the instant gratification economy and simplifying operations. perform more efficiently. The next generation of technology in touch and voice user interfaces and their proliferation via consumer devices produces a better integration of machines in warehouse processes and operations.

The cost of machine maintenance and functionality can be extremely costly to the business. According to WSJ, unplanned downtime costs the industrial manufacturing sector approximately $50 billion annually. Of that downtime, 42% is a direct result of equipment failure. Unplanned downtime or outages produce excessive maintenance, repair, and replacements.

The downtime has a ripple effect that, unrelated to costs, also can hurt tangible and intangible operations resulting in lost revenue opportunities and can damage the brand. Technology like predictive analytics enables manufacturers to mitigate the risk of downtime by understanding and determining the probability of machinery breakdown. This insight is revealed before planning the maintenance window, avoiding costly unplanned downtime.

Manufacturers are increasingly under threat from cyberattacks. Today’s interconnected world invites vulnerability to company supply chains and business models. Successful infiltration for cybercriminals could shut down operations altogether or hurt standard operations.

Most manufacturing firms that are small businesses have yet to implement mature security applications or IT services. While it may not be in the budget, its important that all manufacturing firms take proper precautions by familiarizing themselves with threats or risks in order to protect the company.